How to Measure Mooring Rope Diameter

Accurate measurement of mooring rope diameter ensures safety and efficiency in maritime operations. Knowing how to measure mooring rope diameter is crucial as mooring ropes secure boats and ships, providing stability during docking and anchoring. Various types of mooring ropes include polyester mooring ropes, synthetic fiber mooring ropes, and high-strength synthetic fibers for offshore applications.

Each type offers unique benefits such as high breaking load, good abrasion resistance, and UV resistance. Tools like calipers, measuring tapes, and micrometers assist in determining the correct diameter, ensuring the right fit for specific applications.

Key Takeaways

- Accurate Measurement Ensures Safety: Precise measurement of mooring rope diameter guarantees the safety of maritime operations. Incorrect measurements can lead to equipment failure and accidents.

- Different Types of Mooring Ropes: Understanding various mooring ropes, such as polyester, synthetic fiber, and high-strength synthetic fibers, helps in selecting the right rope for specific applications. Each type offers unique benefits like high breaking load, abrasion resistance, and UV resistance.

- Importance of Tools: Using the correct tools, such as calipers, measuring tapes, and micrometers, ensures accurate measurement of rope diameter. Each tool has specific methods for use, which contribute to precise results.

- Step-by-Step Process: Following a systematic approach to measure mooring rope diameter includes preparing the rope, using appropriate tools, and recording measurements accurately. This process minimizes errors and ensures consistency.

- Common Mistakes to Avoid: Awareness of common mistakes, such as incorrect tool usage, environmental factors, and human errors, helps in preventing inaccurate measurements. Proper training and adherence to best practices reduce these risks.

- Specifications and Standards: Adhering to industry standards and specifications for mooring ropes ensures compatibility and reliability. Understanding these standards aids in making informed decisions during rope selection and maintenance.

Table Representing Mooring Rope Diameters

Accurate measurement of mooring rope diameters ensures the proper selection and application of ropes in maritime operations. Different materials and constructions affect the required diameter for specific uses. The following table provides a comparative overview of common mooring rope diameters based on material type:

Key Insights:

- Polypropylene Ropes: Require a thicker diameter due to lower tensile strength compared to synthetic fibers. Ideal for applications where buoyancy is crucial.

- Polyester Ropes: Offer high strength with slightly thinner diameters. Suitable for high-load applications requiring durability and resistance to environmental factors.

- Polyamide (Nylon) Ropes: Provide excellent shock absorption with moderate diameters. Commonly used in dynamic mooring situations where elasticity is beneficial.

- High-Strength Synthetic Fibers: Allow for thinner diameters while maintaining superior strength. Preferred in demanding offshore applications where weight reduction is essential.

- Natural Fiber Ropes: Typically have larger diameters due to lower strength. Used in traditional settings where biodegradability and cost are considerations.

Understanding these diameter ranges and characteristics helps in selecting the appropriate mooring rope for specific maritime needs. Accurate measurement and knowledge of material properties ensure safety and efficiency in rope applications.

Understanding Mooring Rope Specifications

Types of Mooring Ropes

Synthetic Ropes

Synthetic ropes dominate the maritime industry due to their versatility and performance. Polyester mooring ropes offer high elongation, a high breaking load, and good abrasion resistance. These ropes also resist UV damage, making them ideal for prolonged exposure to sunlight. Double-braid mooring ropes with polyester fibers in both the core and cover provide enhanced durability.

Polyamide (Nylon) ropes exhibit high elasticity and excellent shock absorption. These characteristics make nylon ropes suitable for dynamic mooring situations. High-strength synthetic fiber ropes, such as those made from HMPE (High Modulus Polyethylene) and LCP (Liquid Crystal Polymer), withstand harsh marine environments. These ropes are lightweight yet robust, offering superior strength and flexibility.

Natural Fiber Ropes

Natural fiber ropes, including those made from materials like manila and sisal, have been used traditionally in maritime operations. These ropes are biodegradable and cost-effective. However, natural fiber ropes generally possess lower strength compared to synthetic alternatives. Their susceptibility to rot and degradation under harsh environmental conditions limits their use in modern applications.

Wire Ropes

Wire ropes consist of multiple strands of metal wire twisted together. These ropes offer exceptional strength and durability. Wire ropes are often used in heavy-duty mooring applications where high load capacity is essential. The metal construction provides resistance to abrasion and cutting, ensuring longevity even under strenuous conditions.

Importance of Diameter in Mooring Ropes

Load Capacity

The diameter of a mooring rope directly influences its load capacity. Thicker ropes can handle higher loads, making them suitable for securing larger vessels. Accurate measurement ensures the selected rope meets the required load specifications, preventing failures during critical operations.

Durability

Rope diameter also affects durability. Thicker ropes generally exhibit greater resistance to wear and tear. This increased durability extends the lifespan of the rope, reducing the frequency of replacements. Proper diameter selection ensures the rope withstands the environmental stresses encountered during maritime operations.

Safety Considerations

Safety remains a paramount concern in maritime activities. The correct diameter ensures the rope performs reliably under expected loads. Incorrect diameter selection can lead to catastrophic failures, endangering lives and property. Adhering to industry standards and specifications for rope diameter enhances operational safety and reliability.

Tools Required for Measuring Mooring Rope Diameter

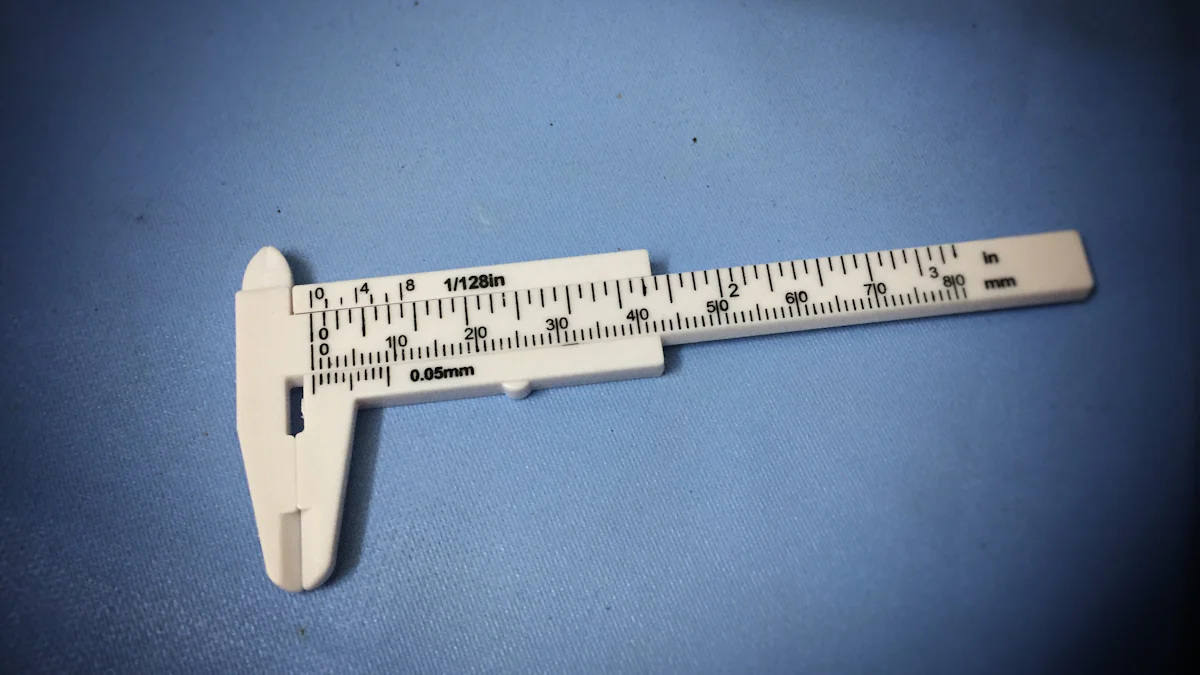

Calipers

Calipers provide precise measurements of mooring rope diameters. These tools come in various types, each suited for specific applications.

Types of Calipers

- Vernier Calipers: Offer high accuracy with a vernier scale for precise readings.

- Digital Calipers: Provide digital readouts, making measurements easy to read and reducing human error.

- Dial Calipers: Use a dial gauge for measurement, suitable for quick and straightforward readings.

How to Use Calipers

- Prepare the Rope: Ensure the rope is straight and clean.

- Position the Caliper: Open the caliper jaws and place them around the rope, ensuring the jaws touch the outermost strands.

- Measure the Diameter: Close the jaws gently to avoid compressing the rope. Read the measurement from the scale or digital display.

Measuring Tapes

Measuring tapes offer a simple method for measuring mooring rope diameters. These tools are versatile and easy to use.

Types of Measuring Tapes

- Fiberglass Measuring Tapes: Resistant to stretching and suitable for outdoor use.

- Steel Measuring Tapes: Provide durability and precision, ideal for heavy-duty applications.

- Cloth Measuring Tapes: Flexible and lightweight, suitable for quick measurements.

How to Use Measuring Tapes

- Wrap the Tape: Wrap the measuring tape around the circumference of the rope.

- Mark the Measurement: Note the point where the tape overlaps.

- Calculate the Diameter: Divide the circumference by π (3.14159) to obtain the diameter.

Micrometers

Micrometers offer high precision for measuring small diameters. These tools are essential for detailed measurements.

Types of Micrometers

- Outside Micrometers: Measure external dimensions with high accuracy.

- Digital Micrometers: Provide digital readouts for ease of use and precision.

- Depth Micrometers: Measure depths and thicknesses, useful for specialized applications.

How to Use Micrometers

- Align the Micrometer: Place the micrometer around the rope, ensuring the anvil and spindle touch the outer strands.

- Adjust the Spindle: Turn the ratchet stop until the spindle gently contacts the rope.

- Read the Measurement: Read the measurement from the scale or digital display.

Table for Tools Required for Measuring Mooring Rope Diameter

Accurate measurement of mooring rope diameter relies on the use of specific tools. Each tool offers unique advantages and methods for obtaining precise measurements. The following table outlines the essential tools required for measuring mooring rope diameter, along with their key characteristics and usage instructions:

Understanding the proper use of each tool ensures accurate measurement of mooring rope diameter. This accuracy guarantees the safety and reliability of maritime operations.

Step-by-Step Guide to Measuring Mooring Rope Diameter

Preparing the Rope for Measurement

Ensuring the Rope is Clean

Cleanliness plays a crucial role in accurate measurement. Dirt and debris can affect the diameter reading. Use a brush or cloth to remove any particles from the rope's surface. Ensure the rope is free from contaminants before proceeding.

Straightening the Rope

A straight rope ensures a precise measurement. Lay the rope on a flat surface. Gently pull both ends to remove any kinks or twists. A straightened rope provides a consistent diameter reading.

Measuring Techniques

Using Calipers

Calipers offer precise diameter measurements. Follow these steps to measure with calipers:

- Prepare the Rope: Ensure the rope is clean and straight.

- Position the Caliper: Open the caliper jaws and place them around the rope, touching the outermost strands.

- Measure the Diameter: Close the jaws gently to avoid compressing the rope. Read the measurement from the scale or digital display.

Using Measuring Tapes

Measuring tapes provide a simple method for determining rope diameter. Follow these steps:

- Wrap the Tape: Wrap the measuring tape around the rope's circumference.

- Mark the Measurement: Note the point where the tape overlaps.

- Calculate the Diameter: Divide the circumference by π (3.14159) to obtain the diameter.

Using Micrometers

Micrometers offer high precision for small diameters. Follow these steps:

- Align the Micrometer: Place the micrometer around the rope, ensuring the anvil and spindle touch the outer strands.

- Adjust the Spindle: Turn the ratchet stop until the spindle gently contacts the rope.

- Read the Measurement: Read the measurement from the scale or digital display.

Recording and Verifying Measurements

Documenting Measurements

Accurate documentation ensures consistency. Record each measurement immediately after taking it. Use a logbook or digital device for this purpose. Consistent documentation helps in tracking and verifying data.

Cross-Verification

Cross-verification ensures accuracy. Measure the rope diameter multiple times using different tools. Compare the readings to identify any discrepancies. Consistent results across different tools confirm the accuracy of the measurements.

Table for Step-by-Step Guide to Measuring Mooring Rope Diameter

Accurate measurement of mooring rope diameter involves several steps. The following table outlines each step, ensuring precision and consistency in the process.

Note: Each tool offers unique advantages. Calipers provide high accuracy, measuring tapes offer simplicity, and micrometers ensure precision for small diameters.

Understanding how to measure mooring rope diameter accurately ensures safety and reliability in maritime operations. Proper preparation and the right tools guarantee precise measurements, reducing the risk of equipment failure.

Common Mistakes and How to Avoid Them

Incorrect Tool Usage

Misalignment

Misalignment of measuring tools can lead to inaccurate readings. Ensure calipers, measuring tapes, and micrometers align perfectly with the rope's outer strands. Misalignment often occurs when the tool does not sit perpendicular to the rope. Always double-check the alignment before recording any measurements.

Inconsistent Pressure

Applying inconsistent pressure while using tools like calipers and micrometers can distort the diameter measurement. Excessive pressure compresses the rope, resulting in a smaller reading. Insufficient pressure may cause the tool to slip, leading to an inaccurate measurement. Maintain a gentle yet firm grip to ensure consistent pressure.

Environmental Factors

Temperature Variations

Temperature variations can affect the material properties of mooring ropes. Synthetic fibers like polyester and polyamide may expand or contract with temperature changes. Measure the rope diameter in a controlled environment to minimize these effects. Avoid taking measurements under direct sunlight or extreme temperatures.

Humidity Effects

Humidity can impact natural fiber ropes, causing them to swell. This swelling alters the diameter, leading to inaccurate readings. Measure natural fiber ropes in a dry environment to avoid this issue. Store ropes in a moisture-free area to maintain their integrity.

Human Errors

Inaccurate Reading

Inaccurate readings often result from misinterpreting the scale on measuring tools. Ensure proper training in reading vernier scales, digital displays, and dial gauges. Double-check each reading to confirm accuracy. Use tools with clear and easy-to-read scales to minimize errors.

Misrecording Data

Misrecording data can lead to significant discrepancies. Document each measurement immediately after taking it. Use a logbook or digital device for accurate record-keeping. Cross-verify recorded data with multiple measurements to ensure consistency.

Conclusion

Accurate measurement of mooring rope diameter is vital for ensuring safety and efficiency in maritime operations. Precision in measurement prevents equipment failure and accidents. Use calipers, measuring tapes, and micrometers correctly to achieve accurate results. Maintain a clean and straight rope for consistent readings. Follow best practices and industry standards to enhance reliability and performance. Understanding how to measure mooring rope diameter accurately ensures that maritime operations remain safe and effective.

FAQ's for Mooring Rope Diameter

What Tools Are Best for Measuring Mooring Rope Diameter?

Calipers, measuring tapes, and micrometers provide accurate measurements. Vernier calipers offer high accuracy with a vernier scale. Digital calipers provide easy-to-read digital displays. Dial calipers use a dial gauge for quick readings. Fiberglass, steel, and cloth measuring tapes offer versatility. Outside, digital, and depth micrometers ensure precision for small diameters.

How Does Rope Material Affect Diameter Measurement?

Different materials require different diameter considerations. Polypropylene ropes need thicker diameters due to lower tensile strength. Polyester ropes offer higher breaking loads with thinner diameters. Polyamide (nylon) ropes provide excellent shock absorption with moderate diameters. High-strength synthetic fibers allow for thinner diameters while maintaining superior strength.

Why Is Accurate Measurement of Mooring Rope Diameter Important?

Accurate measurement ensures safety and efficiency in maritime operations. Incorrect measurements can lead to equipment failure and accidents. Proper diameter selection ensures the rope meets load specifications, enhancing durability and safety.

How Do Environmental Factors Influence Rope Diameter?

Temperature variations can cause synthetic fibers like polyester and polyamide to expand or contract. Humidity affects natural fiber ropes, causing them to swell. Measure ropes in controlled environments to minimize these effects. Avoid direct sunlight and extreme temperatures during measurement.

What Are Common Mistakes When Measuring Mooring Rope Diameter?

Misalignment of tools leads to inaccurate readings. Ensure calipers, measuring tapes, and micrometers align perfectly with the rope's outer strands. Inconsistent pressure while using tools can distort measurements. Maintain a gentle yet firm grip to ensure consistent pressure.

How Can One Ensure Consistent Measurements?

Document each measurement immediately after taking it. Use a logbook or digital device for record-keeping. Cross-verify measurements by using different tools. Consistent results across various tools confirm accuracy.

What Are the Key Characteristics of Different Mooring Ropes?

Polypropylene ropes are lightweight and float on water. Polyester ropes offer high strength and abrasion resistance. Polyamide ropes provide high elasticity and shock absorption. High-strength synthetic fibers are lightweight and UV resistant. Natural fiber ropes are biodegradable and cost-effective.

How Does Rope Diameter Affect Load Capacity?

Thicker ropes handle higher loads, making them suitable for larger vessels. Accurate measurement ensures the selected rope meets required load specifications. This prevents failures during critical operations.

What Are the Benefits of Using Synthetic Ropes?

Synthetic ropes dominate the maritime industry due to versatility and performance. Polyester mooring ropes offer high elongation and good abrasion resistance. Polyamide ropes exhibit high elasticity and excellent shock absorption. High-strength synthetic fiber ropes withstand harsh marine environments.

How Should One Prepare a Rope for Measurement?

Ensure the rope is clean by removing dirt and debris. Straighten the rope by laying it on a flat surface and gently pulling both ends. A clean and straight rope provides a consistent diameter reading.